How is coal converted to electricity?

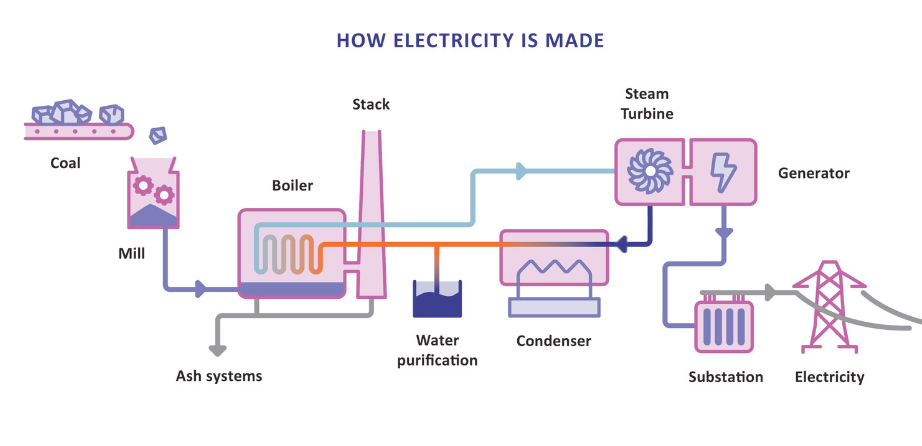

Steam coal, also known as thermal coal, is used in power stations to generate electricity. First coal is milled to a fine powder, which increases the surface area and allows it to burn more quickly.

- In pulverised coal combustion (PCC) systems, the powdered coal is blown into the combustion chamber of a boiler where it is burnt at high temperature.

- The hot gases and heat energy produced converts water in tubes lining the boiler into steam.

- The high-pressure steam is passed into a turbine containing thousands of propeller-like blades.

- The steam pushes these blades causing the turbine shaft to rotate at high speed.

- A generator is mounted at one end of the turbine shaft and consists of carefully wound wire coils.

- Electricity is generated when these are rapidly rotated in a strong magnetic field.

- After passing through the turbine, the steam is condensed and returned to the boiler to be heated once again.

- The electricity generated is transformed into the higher voltages up to 400,000 volts used for economic, efficient transmission via power line grids.

- When it nears the point of consumption, such as our homes, the electricity is transformed down to the safer 100-250 voltage systems used in the domestic market.

Efficiency improvements

Improvements continue to be made in conventional PCC power station design and new combustion technologies are being developed. These allow more electricity to be produced from less coal less coal being used to produce the same amount of electricity results in lower emissions. This is known as improving the thermal efficiency of the power station.

High Efficiency Low Emissions (HELE) plants – Supercritical, Ultrasupercritical and Advanced Ultrasupercritical – work in a similar fashion to conventional plants but operate at higher temperatures and pressures.

Supercritical boilers have higher efficiencies than subcritical coal combustion due to increased steam parameters. In supercritical systems, the steam reaches a supercritical state rather than boiling. The improved supercritical steam cycles involve higher temperatures and higher pressures which result in high efficiencies and lower coal consumption.

Integrated Gasification Combined Cycle (IGCC)

- In IGCC systems, coal is not combusted directly but reacted with oxygen and steam to produce a ‘syngas composed mainly of hydrogen and carbon monoxide.

- This syngas is then cleaned of impurities and burnt in a gas turbine to generate electricity and to produce steam for a steam power cycle.

- Heat from the gasification and gas cleaning stages can also be used within the steam cycle or for the air separation unit (compressed air).